A roof protects a home from rain, snow, sunlight, and temperature extremes. Storm Tech Roofers can add beauty and value.

There are many roofing choices. Some are simple, such as asphalt shingles or sheet metal. Others are more complex, such as clay or slate tiles. The most important thing is that the roof dries quickly and efficiently to prevent water damage inside the home.

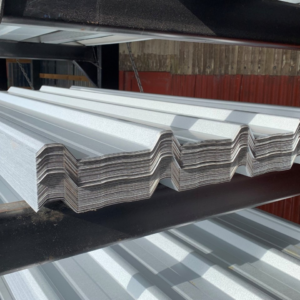

Sheet metal is a type of material used to create a variety of products and parts. It comes in a wide range of thicknesses, from extremely thin pieces to thicker sheets that are used as roofing materials. It can be made from a number of metals, including cold rolled steel, aluminium, brass, tin and copper. It can also be made of other alloys, such as nickel and titanium.

Traditionally, sheet metal has been a common choice for industrial and commercial buildings. However, it has recently become a popular option for homes as well. This is due to the fact that it is long-lasting, durable and energy efficient. It is also able to reflect solar radiation, which helps to reduce cooling costs. Additionally, it is environmentally friendly, and there are often tax incentives for using this type of roof.

There are a few different ways that this type of roofing can be constructed. Some use a standing seam, which has no exposed fasteners. Others, like corrugated metal, use a rolled design that creates wavy seams that overlap each other. A third style of roof uses a shingle-like panel that can be pre-fabricated or formed on site. These panels can be joined together by either clipping the female leg to the male leg or using a nail flange.

These panels can be made of a variety of different alloys. They can also be shaped in various ways to give the structure a unique appearance. They can even be coloured to add a decorative element to the roof. This makes them a versatile roofing option that can complement a variety of styles.

Throughout the world, sheet metal is used in an incredible variety of applications. It is found in intense industries such as automotive, mining, aviation and manufacturing. We also see it in everyday items, such as the metal surround on a kitchen bench top or a unique punched metal screen that is used for an interior design feature. It is also an excellent roofing material, as it can withstand extreme weather conditions. It is also fire resistant and noncombustible, making it a great choice for homes in communities that are prone to wildfires.

Asphalt shingles are one of the most common roofing materials. They are easy to install and offer a wide variety of colors, textures, and styles to match the aesthetic of your home. They also provide excellent durability and resistance to different weather conditions. However, they are not as strong as other roofing materials and may not be the best option for areas that experience a lot of wind.

Typically made from a fiberglass base with a coating of composition asphalt, these shingles are available in several different options to meet the needs and budgets of homeowners. They are a great choice for homes with moderate to steep slopes. They are also known as laminated shingles, which is due to the fact that they are constructed of multiple layers. These layers are then covered with ceramic granules to protect the roof from different weather elements and enhance its appearance.

There are four different types of asphalt shingle roofs: three-tab shingles, architectural shingles, upgraded architectural shingles, and luxury or designer shingles. Each performs a different function depending on the look you want and the purposes your roof is designed to serve.

Three-tab shingles are the most basic type of asphalt shingle. They have a single layer, are thinner than architectural shingles, and are not as durable. These shingles are often the most affordable and used in low-value homes. Architectural shingles are thicker and have a more dimensional appearance on the roof. They are also more durable and can withstand stronger winds than three-tab shingles. They are often the most popular shingle style for homes

Upgraded architectural shingles are thicker and have more layers than regular architectural shingles. They are a bit more expensive but offer a higher level of durability. They are often the choice for homeowners looking to add a more premium and elegant appearance to their roof. They are also often more energy-efficient than three-tab and architectural shingles.

Luxury or designer shingles are the highest-end shingles on the market and designed to simulate the appearance of wood shakes or natural slate tile roofs. They are more expensive but offer the most premium and attractive appearance on your roof. They are usually the most durable as well, offering a 50-year non-prorated manufacturer warranty.

When most people think about the “face” of a roof, they probably imagine asphalt shingles, cedar shakes, rubber membranes or other materials. But these surface materials are only half of the story – underneath them are layers that protect and contribute to a roof’s resilience against exposure elements such as rain, wind, snow, hail, ice, fire and sun. During a roof inspection, it’s important to assess the condition of these underlayment layers as well.

A key function of underlayment is to repel water and prevent moisture from penetrating the roof deck in the early stages of a new construction project. Builders and roofers refer to this as the “dry in” phase of a roofing job. For reroofing, underlayment also helps to repel moisture and prevent the growth of mold, mildew, fungus or other damaging organisms.

There are several different types of underlayment material, with the most common used in residential, steep-slope applications being black, ashphalt-saturated felt paper. This product may be produced with either a cellulose or fiberglass base material, and is generally available in 15-pound and 30-pound versions. Fifteen-pound felt is less expensive but does not offer the same level of water resistance as 30-pound felt.

Some roofers also use a variety of synthetic underlayment materials. These are typically manufactured with polypropylene or polyethylene, which are the same basic materials that are used to make a wide range of other products including food containers, rope and long underwear. These synthetic underlayment materials are lighter than felt, and are usually non-skid. Rolls of this type of underlayment are often provided with a selvedge edge along one side, which creates a strong, watertight seal where rolls overlap.

Many roofers use a combination of felt and synthetic underlayment for their projects, depending on the needs of each project and client. All underlayment should be installed in accordance with the manufacturer’s guidelines, and building codes for the particular roof system style. In general, underlayments should have a permeance rating of at least 5 perms – or allow water vapor to pass through but resist liquid water penetration.

Flashing is a thin material that professional roofers install around critical areas of the roof, where it meets a vertical surface like a wall or dormer. Its purpose is to prevent leaks where water might otherwise seep into the wall or into the roof itself. There are several types of flashing designed for specific features, such as chimneys and roof windows.

There are also specialty flashings, such as ridge cap flashing, which is installed at the peak of the roof to create a waterproof seal. Vent pipe flashing is another specialty flashing that protects the roof where pipes penetrate it. Flashing also comes in different shapes and sizes to suit a particular situation, such as f-shaped drip edge flashing, which is often used on tile roofs, or valley flashing, which is often installed to protect the area where two different slopes of a roof meet.

Most flashing is made of metal, and the most common is galvanized steel. However, aluminum, lead, and other malleable materials may also be used for flashing. There are pros and cons to each type of material, and it depends on the situation and the environment in which the flashing will be installed.

For example, galvanized steel is an economical choice for most flashing applications because it’s inexpensive and durable. However, it can rust in salty seaside environments or when it comes into contact with masonry. Aluminum is another economical option, but it doesn’t last as long as copper or zinc alloy and requires coating to prevent corrosion. Lead is also a flexible material, but it’s less durable than other options and can leach toxic chemicals into the soil.

Although flashing doesn’t require regular maintenance, it should be inspected periodically for signs of damage or leaks. This includes checking for cupping shingles, swollen or sagging areas, rust stains, water stains in vulnerable or odd areas of the roof, and interior leaks. If you notice any of these symptoms, it’s a good idea to call a roofing contractor as soon as possible. They can better identify the source of the problem and repair or replace any damaged flashing.