Home » Articles posted by Amaya Hood

Author Archives: Amaya Hood

Porta Potty Rental Costs

Renting portable restrooms for events and construction projects is an affordable way to address onsite sanitation. Modern porta potties also support sustainable and eco-friendly waste management practices.

The cost of a porta potty rental varies depending on the unit type and duration. Standard special event units are usually a one-time fee, while luxury restroom trailers can be rented for longer periods. Contact Reliable Port A Potty now!

The cost of potty rental can vary significantly depending on the type and location. Some companies charge higher rates for more luxurious units, while others offer lower prices for standard models with basic features. Other factors that influence the price include the duration of the rental, delivery and setup fees, and additional services such as waste disposal and cleaning. Understanding these variables can help you budget effectively for your project or event.

For example, the cost of a standard porta-potty with two stalls can be around $75 to $100 per day. This includes delivery, setup, and pickup fees. In addition, you should consider the number of people attending your event and how long they will be there. A good rule of thumb is to rent one portable toilet for every 50 attendees and four hours of activity.

When it comes to choosing a potty rental company, you should research the options available to find a company with transparent pricing and top-tier service. Some companies may lure customers in with low base prices, but then add on a plethora of hidden charges. Choosing a reputable provider with a proven track record of reliability and customer reviews can save you money and stress in the long run.

The average cost of a potty rental is about $80 to $175 for a short-term rental that lasts from a few days to a week. Some companies even offer package deals that include multiple units at a discounted rate. This is a great option for outdoor weddings, backyard parties, festivals, and concerts.

In addition to the cost of a portable toilet, you should also consider the cost of any additional services or amenities you might need, such as air conditioning, sophisticated furnishing, and handicap accessibility. While these upgrades can add to the overall cost of a portable toilet, they can provide a better experience for your guests and ensure that your event is safe and comfortable.

For longer-term projects or events, it is best to negotiate a monthly rental contract with the portable toilet company. This will allow you to save more money on the cost of transportation, cleaning, and maintenance. In addition, a monthly contract will provide you with peace of mind that you will have portable toilets available when you need them.

Unit type

The type of porta potty rental you choose can have a significant impact on the cost. You can find basic standard units, deluxe models with more amenities, and even luxury portable restroom trailers. Choosing the right unit type is key for a successful event or construction project. It is also important to understand the daily rental costs, which typically include delivery and setup fees. This can help you budget accurately for your specific needs.

The unit type of porta potty rental you need depends on the size of the crowd and the length of time you need the unit. For example, a temporary construction site may require standard portable toilets, while an outdoor concert or wedding might call for a deluxe model. It’s also important to consider the location of your unit. You want to make sure that it is conveniently located and out of the way of ongoing work. You can also save money by renting multiple units at once.

You should ask your rental company for a detailed quote that includes all charges. These fees can include a damage waiver fee, reservation fee, fuel surcharge, waste-handling, cleaning and maintenance, premium charge, and more. A reputable porta potty rental company will offer transparent pricing and top-tier service.

When choosing a porta potty rental, be sure to compare the quality and features of different units to make the best choice for your needs. Some companies may lure you in with low base prices but add in a lot of hidden fees. Others, like Viking Rentals, prioritize transparent pricing and high-quality service.

Some additional tips for budgeting for portable toilet rental costs include assessing the duration of your project and estimating the daily numbers of people you will be serving. It’s also a good idea to overestimate your numbers, as this will help you avoid situations where the number of people exceeds the amount of facilities available.

If possible, rent portable toilets during off-peak times. This will save you money and ensure that you get the best units for your budget. This is especially important for large events and long-term projects, as these units are more likely to be in high demand during peak seasons.

Delivery and setup

Whether you’re hosting a music festival in Brooklyn, organizing an outdoor event in Queens or preparing for a construction project in New York City, human waste disposal is likely to be an issue. Luckily, there are many ways to minimize costs without sacrificing convenience. By planning ahead, renting in bulk and choosing basic units, you can save money on your porta potty rental while ensuring adequate facilities for your guests or workers.

The standard portable toilets most people are familiar with are small, portable restroom stalls made of lightweight plastic that are used at events and on construction sites. They are equipped with a toilet and urinal, as well as soap and paper towels. They also contain blue deodorizing chemicals to disinfect the unit and manage waste. In addition, most rental companies provide toilet paper and hand sanitizer dispensers. They may also offer a handwashing station that includes a sink, soap and paper towel dispensers.

Porta potty rental fees vary depending on the type of unit and its location. Some rentals include a tank and delivery, while others have additional charges for cleaning, waste disposal, and site cleanup. These fees should be clearly explained in the contract, so you can make an informed decision. It’s also important to understand how pricing changes during peak seasons, when demand is high.

Most rental companies have a basic chart that provides recommendations for the number of units needed for various events. However, these recommendations can vary, and you should always consult with the supplier to ensure that your event is properly planned. For example, two standard portable toilets are enough for a concert with under 1,000 people. For construction sites, one portable toilet per 10 workers is recommended.

When you rent a porta potty, the rental company will deliver it to your site and set it up. They will need a clear pathway to the location and a truck or trailer with a mechanical lift to unload the unit from the back of the truck. They will then lower the unit from the tailgate and straps, and place it on a stand or other foundation. Once the rental period is over, the company will come back to retrieve it and dispose of the waste.

What You Should Know About Invisalign

Invisalign Las Vegas is a treatment option that can correct a variety of orthodontic issues. This includes overcrowding, gaps between teeth and various bite problems.

The process starts with a consultation with an Invisalign-trained doctor. Using advanced 3D scanning technology, they will create a customized treatment plan for your specific needs. This personalized approach provides the best results and addresses any complex alignment issues that might not be addressed by generic mail-in aligners.

Invisalign uses clear plastic trays to straighten teeth without the visible wires and brackets that are often associated with traditional braces. The trays are nearly invisible and blend in with the natural color of your teeth, making them an ideal choice for adults who are concerned about how their orthodontic treatment will affect their appearance. Invisalign also has a shorter treatment time than traditional braces, which can be an important consideration for busy adults.

Like any orthodontic treatment, there is a chance that you will experience mild pain or discomfort while wearing Invisalign. Typically, this discomfort is highest during the first week of wear. However, it can vary based on your individual pain tolerance. It is also possible that you may not feel any pain at all during your Invisalign treatment. If you do experience pain, a visit to your Bolton orthodontist can help determine whether it is an indication that the trays are working as intended or if there is a more serious issue that needs to be addressed.

You can reduce the amount of pain you feel while you are wearing Invisalign by brushing your teeth after each meal and before putting your trays back in. This will help remove any food debris that could irritate your gums and tongue. You can also use a toothpaste that is specifically formulated for sensitive teeth. You should also avoid using hot water to clean your Invisalign trays, as this can cause them to warp and negatively impact the fit of the trays.

One of the biggest benefits of Invisalign is that it is more comfortable than traditional braces. Although you can expect a little bit of discomfort when you begin your Invisalign treatment, this should not be as painful as the initial discomfort experienced with metal braces. Invisalign is able to accomplish this because it applies less pressure on your teeth.

Invisalign trays are designed to gently shift your teeth into place over the course of a few months or two years. Each new set of trays is crafted to move your teeth just a little bit more than the previous ones did, helping you get closer to a straighter smile. You will receive a new set of aligners every six to eight weeks until your treatment is complete.

Comfortable

Invisalign uses a series of clear, removable aligners that are custom-made with 3D computer imaging technology to straighten your teeth. They’re comfortable to wear and don’t require metal wires and brackets, so patients can enjoy their favorite foods and activities without any limitations or restrictions. However, it’s important to note that the success of Invisalign treatment depends on a patient’s ability to comply with wearing their aligners for 22 hours a day. This is why it’s best for older teens and adults to choose Invisalign over children, as they may have trouble staying compliant with the treatment plan.

It’s important to know that Invisalign is a gradual process that will shift your teeth gradually. For this reason, it’s possible that you may experience some discomfort or sensitivity as your teeth move and adjust to their new positions. However, this is a normal part of the process and will subside after a few days. Using toothpaste that is designed for sensitive teeth can help mitigate this. If you have any questions or concerns about your comfort, speak with a Maple Dental Health dentist for recommendations.

During your Invisalign treatment, you’ll meet with an experienced dental professional regularly to make sure that you’re on track to achieve a beautiful new smile. They’ll examine your trays to make sure they fit correctly and provide you with each new batch of trays as needed. Regular face-to-face checkups ensure that your progress is being monitored, and any potential problems can be addressed promptly. This is a major advantage of Invisalign over mail-in or DIY aligners, which often rely on self-assessment and remote monitoring.

If you have a high-deductible health insurance plan, an HSA, or another flexible spending account, you may be able to use funds from these accounts toward your Invisalign costs. If not, many dental offices offer flexible payment plans that allow patients to spread out their payments over a year or more.

Invisalign is an excellent choice for adults and teenagers who want a confident new smile. However, children who have a hard time remaining compliant with their Invisalign treatment plan may be better candidates for traditional metal braces.

No Food Restrictions

Many individuals avoid traditional braces because they do not like the idea of having to live with food restrictions. Invisalign’s clear aligners are removable, so you can enjoy any foods that you normally would. However, it is important to remember that the aligners must be removed before drinking anything other than water. Consuming any other beverages can damage the aligners or leave residue on them that will negatively impact your oral health.

Sticky foods, such as chewing gum, jelly beans, or caramels, can pull and tug at the aligners. This can cause them to break or become discolored. Additionally, eating while wearing your aligners exposes them to acid that can weaken the enamel and lead to tooth decay. This can also cause the aligners to wear down, leading to discomfort or a possible loss of alignment.

If you are concerned about the impact of your diet on your Invisalign treatment, the team at Hanson Place Orthodontics recommends eating soft, steamed or grilled foods that do not require much chewing. This will help reduce the risk of gum or other sticky foods causing damage to your aligners. In addition, it is important to safely store your aligners in their case after every meal and follow a proper cleaning routine before reinserting them.

Hard and crunchy foods, such as nuts, ice chips or popcorn, can chip or break the aligners. This can result in pain or a delay in the treatment process. In addition, they can also cause bacteria growth on the teeth and in the mouth that can lead to cavities or gum disease.

The Invisalign treatment schedule requires that you wear your aligners for 20-22 hours a day. If you do not wear your aligners as directed, you may experience a longer treatment time. The best way to stay on track with your Invisalign treatment is to make a habit of consistently wearing your aligners during the day and properly storing them at night. Additionally, be sure to brush and floss your teeth regularly to keep them free of food debris, plaque and bacteria that can harm the teeth and the aligners.

Shorter Treatment Time

When it comes to straightening teeth, Invisalign is significantly faster than metal braces. While it depends on your individual needs, most patients will see results within 12 months. This is in part because the clear aligners are less invasive and require much less maintenance. Invisalign treatment also doesn’t interfere with your daily routine like metal braces can, which makes it easier to keep up with your regular oral hygiene regimen.

The exact length of your Invisalign treatment will vary from patient to patient, however there are some things that you can do to speed up the process and achieve the best results. One of the most important factors is how compliant you are with your orthodontist’s instructions. It’s crucial to wear the clear aligners for as many hours as possible and avoid removing them unnecessarily. If you have trouble remembering to put them in and out, ask your orthodontist to give you a schedule so that you can stay on track with your treatment.

Another factor that impacts your Invisalign treatment time is how severe your misalignment is. Some minor cases of crowding can be corrected in as few as six months, while more severe issues will take closer to a year. If you have gaps between your teeth, known as diastemata, the treatment can be even longer as these will need to be closed before the end of the process.

Your age also has an impact on the length of your Invisalign treatment. Younger patients tend to have more malleable bones, which can make it easier for their teeth and jaws to move. This means that they can often get their desired orthodontic outcome in a shorter period of time than older patients.

Lastly, the type of food you consume has an effect on how long your Invisalign treatment will last. Some foods can slow the movement of your teeth, which will prolong your treatment time. It’s crucial to eat healthy during your Invisalign treatment in order to make it go as quickly and smoothly as possible. By limiting the amount of sugary and crunchy foods you eat, you can ensure that your teeth are moving at a steady pace and achieve the fastest results possible.

Roof Repair – The Unsung Heroes of Roofing

If you see holes, gaps, or visible sagging in your roof, don’t wait to get it repaired. Every day your compromised roof goes unrepaired is another day it’s vulnerable to rain, snow, and other weather.

If you have a shingle roof, you should regularly assess it for signs of damage, including shingles that are coming loose or missing. Missing shingles should be replaced promptly to maintain the integrity of your roof and protect your home from water penetration. If you spot a problem, the good news is that most of the time, it will not require a complete roof replacement. Instead, a simple repair may suffice, mainly if it is addressed quickly. Contact Red Stick Roofing Of Louisiana for professional help.

Before attempting any roof repairs, however, it is crucial to have the right tools and materials at your disposal. If you don’t have the necessary tools, or if you aren’t comfortable working on your own roof, it’s best to hire a professional roofing contractor. With the right equipment and a clear understanding of the steps to take, it is possible to fix a shingle roof yourself.

First, carefully assess the shingle situation from ground level. Ideally, do this after a rainstorm. This will help you see any displaced shingles and will reveal the extent of the damage. It will also help you determine whether the repairs are minor or if a more comprehensive roof replacement is warranted.

Once you’re on the roof, it is important to work safely. Make sure you have a ladder that is stable and that you aren’t leaning against any areas that are already damaged. It is also a good idea to wear rubber gloves and safety goggles during this part of the process, as you will likely be handling sharp debris.

The next step is to gently lift the target shingle. It will be bonded to the shingle above it with asphalt sealant, which can usually be broken by sliding a flat pry bar underneath the edge of the target shingle. This is best done in cool weather, as the sealant will be easier to shear off.

Once you’ve removed the target shingle, remove all of the nails that held it in place. Be careful not to rip any other shingles when doing this, as this can lead to leaks. Next, simply slide the new shingle into place and nail it in. It’s also a good idea to put a dab of roof sealant over the new shingle, as this will help ensure that it holds up against future storms.

Flashing

While roof shingles and gutters tend to get most of the attention in roof repair situations, flashing is one of the unsung heroes of roofing. Flashing prevents water penetration into buildings and helps to direct moisture away from walls. It’s usually made of metal and found around the perimeter of vent pipes, chimneys, dormers, window openings and other roof penetrations.

Professional roofers often install flashing to seal leaks that can damage the interior of a home. Without it, moisture would drip into the crevice between the wall and roof decking and potentially leak through the shingles. Flashing also protects areas of the roof that are prone to leaks, such as the inward creases at roof valleys and rake edges.

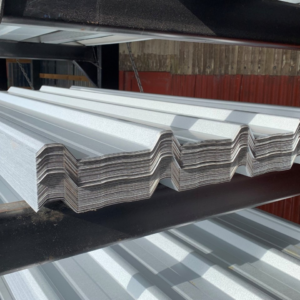

Roof flashing is typically made of galvanized steel or aluminum. It’s installed over the underlayment and underneath the shingles on shingled roofs, or over the top paneling of metal roofs. The flashing is typically sealed with caulk. Flashing is designed to flex as the building expands and contracts during seasonal changes. For this reason, it’s best to install flashing with built-in expansion joints.

There are many different types of flashing. Most commonly, it’s installed in the form of L-shaped pieces that overlap each other like fish scales. The base of each L is nailed to the roof and the top bent up against a vertical surface such as a chimney or dormer.

Another type of flashing is called counter-flashing, and it’s placed above or opposite of the base flashing. This type of flashing is frequently layered at the base of a chimney to prevent water from seeping in between the chimney and roof.

When a home’s flashing is damaged, it’s important to contact a roofing contractor for repairs. A roofing specialist will know how to inspect the area and determine if there’s additional leakage that needs to be addressed. A professional will also be able to spot signs of flashing failure, including cupping shingles, swollen or sagging areas, water stains in vulnerable or odd spots, rust or staining and interior leaks. The roofer will remove shingles as necessary, expose the flashing and repair any damage.

Gutters

Gutters are long troughs attached to the fascia boards at the edge of your roof that catch and carry rainwater away from your house. They prevent moisture from accumulating on the roof and damaging the shingles, siding, soffit (the exposed wood at the underside of the roof overhang) and other structures, including your foundation.

Gutter systems are a critical part of roof repair. Without them, rainwater would flow off your roof and pool around your home’s foundation, causing cracks that could undermine it. Gutter system installation and regular cleaning keep water off your roof and away from your foundation, preventing costly damage to your house and property.

During the course of time, gutters can become clogged with leaves and twigs that are pulled in by storm winds, as well as with other debris. When this happens, the gutters can sag or move away from the roof, reducing their effectiveness. They can also leak, either from the seams or at the downspout elbows, which should be sealed with silicone caulk or metal flashing.

If left unattended, gutters can also get overrun by bugs and rodents looking for shelter or a place to live. These pests can cause rotting, which is not only expensive to fix, but it can also compromise the structure of your house.

The fascia board is the flat piece of wood attached to the bottom edge of your home’s eaves, just below the roof overhang. It serves as the surface that your shingles attach to, and it’s an important part of your roofing system. If it becomes sagging or corroded, you should replace it.

In addition to replacing a sagging or corroded fascia board, you’ll need to replace the shingle underlayment and flashing to prevent water leaks at the joints. This process is usually quite labor-intensive, so it’s best to leave it to the professionals unless you have experience doing it yourself. If you do choose to make the repairs yourself, you should use only high-quality materials to ensure that your new roof is protected for years to come. Using a quality product will help reduce the risk of problems down the road, which can save you a lot of money and stress in the long run.

Attic

The attic is the space directly under the roof and above the top floor of your house. It may be a cramped space barely large enough to fit a box, but it’s important for the safety of your home.

It’s where mold grows and can cause health problems for those living in the home. As such, it’s critical to keep it free of mold spores. If a roof leak occurs, it can allow mold spores to enter the attic and begin growing. Fortunately, roof leaks can be repaired quickly with the help of a professional.

In addition to checking for a roof leak, a professional will inspect your attic for issues such as damaged insulation. Damaged insulation is not only inefficient, but it can also lead to mold and wood rot. This is why it is important to have adequate attic insulation to protect your home from moisture.

A poorly insulated attic can actually make your home more expensive to live in. It allows paid-for heat to escape through the roof. However, improved attic insulation can prevent this from happening and save you money on energy bills.

You can check your attic insulation by looking for cracked housings on plastic roof vents and broken seams on metal ones. You should also look for shiners, which are nails that have missed the framing members and appear white due to frost. These need to be clipped to prevent water from condensing on them and causing damage.

If you are planning to do any work in your attic, it’s best to wear a dust mask. Many types of insulation contain airborne particulates that can cause respiratory issues. You should also be careful not to snag your ceiling joists with your tools or drop anything on them as they may fall through. You should also lay a sheet of plywood across the attic joists to protect them. This is a good idea for any attic repairs, too, as it will protect the attic floor from damage caused by falling tools and materials.